User interface

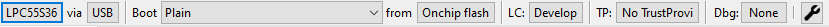

SEC offers a simple and user-friendly interface. It consists of the menu bar, toolbar, and main views accessible through tabs:

Build image allows building a bootable image.

Write image allows writing a bootable image into the processor and optionally securing it.

PKI management allows generating authentication keys or configuring the Signature Provider.

The bottom part of the interface is occupied by the Log window and status line.

Configuration controls that are not supported for the selected processor might not be displayed. If a control is supported for the processor but is not meaningful in the current setting, it is disabled (gray). The tool highlights controls with configuration problems in red (errors) or yellow/orange (warnings). The problem is described in the tooltip. The tool displays information messages in blue.

SEC user interface

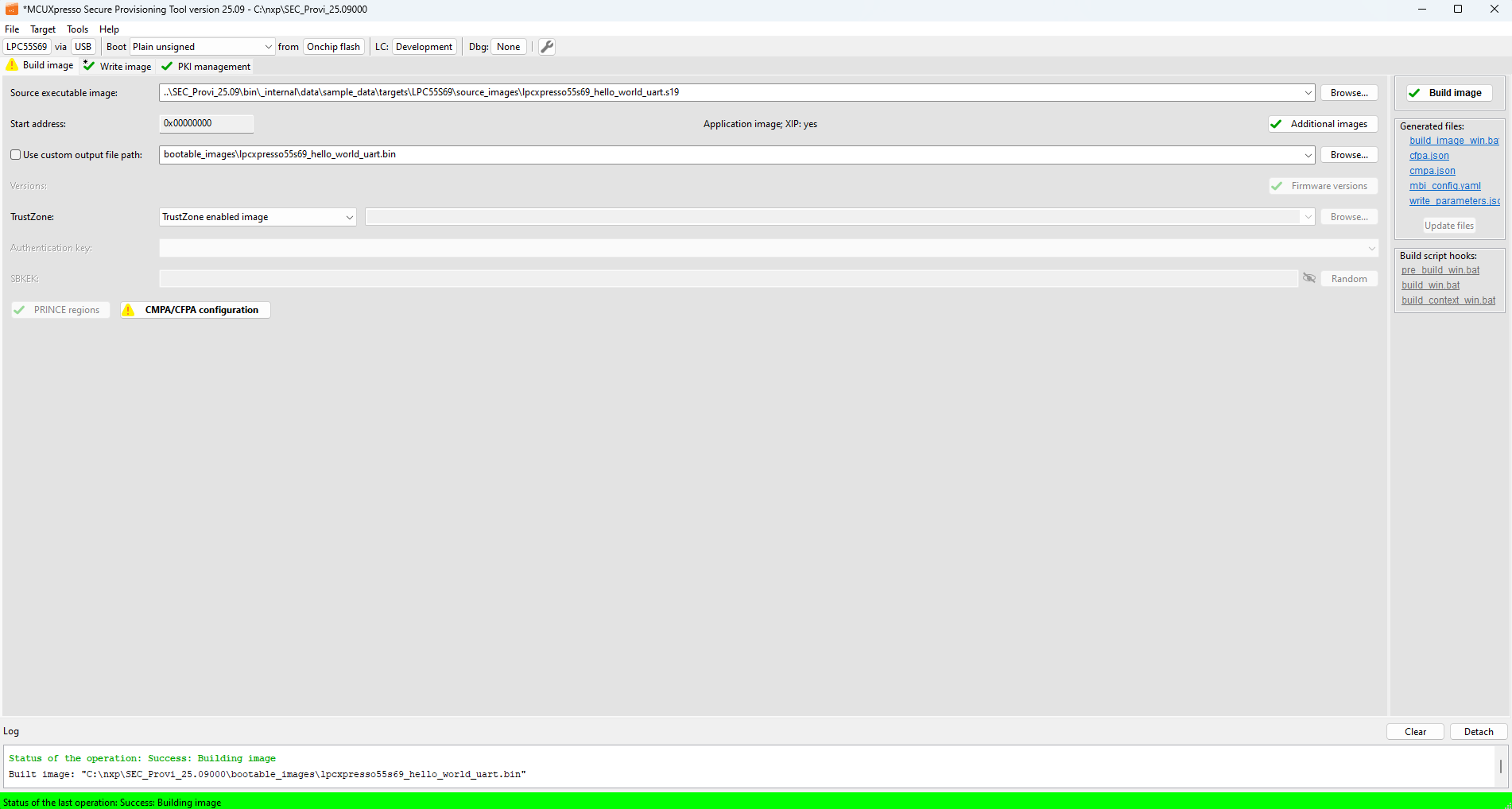

Build image

In the Build image view, you can transform an application image into a bootable format compatible with the selected processor.

Build image (LPC55Sxx)

Controls on the build image view:

Source executable image : Chooses the input executable file. For more information about the input image format, see Source image formats.

Start address : The base address of the image. It is editable only to a binary image. For ELF and S-Record and HEX files, it is detected automatically.

Application/Bootable image and XIP : The label provides the following information about the selected source image:

whether it is an application or a bootable image.

whether the selected source image is built as “eXecuted In Place”, and will be executed from the boot memory, where it is stored. If not, the image must be copied to RAM before the execution. The information is derived from the starting address of the image and compared with the memory address of the selected processor, so the result might not be correct if the selected image does not match the selected processor.

Additional images : Opens the configuration dialog for the Additional User/OEM Image, see Additional images.

Use custom output file path : Name of the generated bootable image file and its location. If not specified, the tool names the image based on the input. The file extension is specific for a processor and a boot type, it is either BIN for bootable images or SB for secure-binary capsules.

Image version : Version of the bootable image. It is used for dual image boot. The image with the higher image version is booted first.

Dual image boot : Opens the configuration window for dual image ping-pong boot. Image can be written to the base (image0) and/or to the remapped (image1) space of the flash, each of the them has its own image version. The ROM then uses the image version to select the latest image to boot. If the latest image boot fails, the old image is used to boot again.

Firmware versions : Opens the configuration dialog of Firmware versions (Secure and Non-secure). The firmware version allows setting the anti-rollback protection. For details, see Firmware versions.

XMCD : Allows enabling the External Memory Configuration Data feature. XMCD is needed for comprehensive or feature-rich applications requiring large capacity of RAM (on-chip RAM is not enough). Either a YAML or BIN configuration file can be provided or XMCD simplified configuration can be prepared in XMCD configuration dialog. (for details, see the description of the –xmcd-cfg CLI parameter).

DCD (Binary) : Selection of what Device Configuration Data must be included in the bootable image. The option From source image can be used only if the source image contains DCD. The DCD enables early configuration of the platform including SDRAM. MCUXpresso Config Tools can generate a DCD in a compatible format. If the target processor does not support DCD files, the checkbox is disabled. For more information, see Creating/Customizing DCD files.

TrustZone : Allows you to enable TrustZone features. The following selection is possible:

TrustZone disabled image - Disables TrustZone. This option is not supported for some processors.

TrustZone enabled image - Enables TrustZone with the default configuration preset in the processor.

TrustZone enabled image with preset data - Enables TrustZone with custom TrustZone-M data. JSON and BIN file formats are supported. JSON data can be generated in and exported from the TEE Tool of MCUXpresso Config Tools. BIN file is created by the

nxpimageutility. For more information, see TrustZone configuration file.

Authentication key : Signs the image with the specified key. The key can also be used for the authentication of the SB file. This option is only applicable to authenticated and encrypted boot modes and offers a selection of keys generated in the PKI management view.

Key id : The keyblob encryption key identifier is used in the encrypted (AHAB) boot type

AHAB/HAB encryption algorithm : Selection of AHAB/HAB encryption algorithm used in the encrypted (HAB), authenticated, or encrypted (AHAB) boot types.

Key source : A key source for signing the image.

User key : For the OTP key, the source master key is used to derive other keys. For the PUF KeyStore, the user key is used to sign the image. Only available for Plain signed boot types.

SBKEK, SB3KDK, or CUST_MK_SK : A key is used as a key-encryption key to handle an SB file. Only available for secured boot types. For RT5xx/6xx, it is only enabled when the key source is KeyStore. For LPC55Sxx devices, the key store is initialized only once in the device life cycle and after that, any change in SBKEK will cause failure to load the SB file into the processor. For more information, see PFR and PUF KeyStore. OEM seeks a hex key used to randomize the creation of the SB file with the CUST_MK_SK key.

Configuration dialogs : The following configuration dialogs are available on the Build image view:

XIP encryption (BEE user keys) : Opens the configuration dialog of XIP encryption user keys. Option enabled only for XIP encrypted (BEE user keys) authenticated and XIP encrypted (BEE user keys) unsigned boot types.

XIP encryption (BEE OTPMK) : Opens the configuration window of BEE with the OTP Master Key. The option is enabled only for XIP encrypted (BEE OTPMK) authenticated boot type.

IEE encryption : Opens the configuration dialog of IEE encryption. The option is enabled only for IEE encrypted boot types.

OTFAD encryption : Opens the configuration dialog of OTFAD encryption. Option enabled only for OTFAD encrypted boot types. For RT10xx devices, the button name is XIP encryption (OTFAD user keys).

XIP encryption (OTFAD OTPMK) : Opens a configuration window of OTFAD with OTP Master Key. The option is enabled only for XIP encrypted (OTFAD OTPMK) authenticated boot type.

PRINCE/IPED regions : Opens a configuration window for encrypted PRINCE/IPED regions allowing specifying which flash regions will be encrypted.

OTP/PFR/IFR/BCA/FCF configuration : Opens OTP/PFR/IFR/BCA/FCF configuration.

Generated files

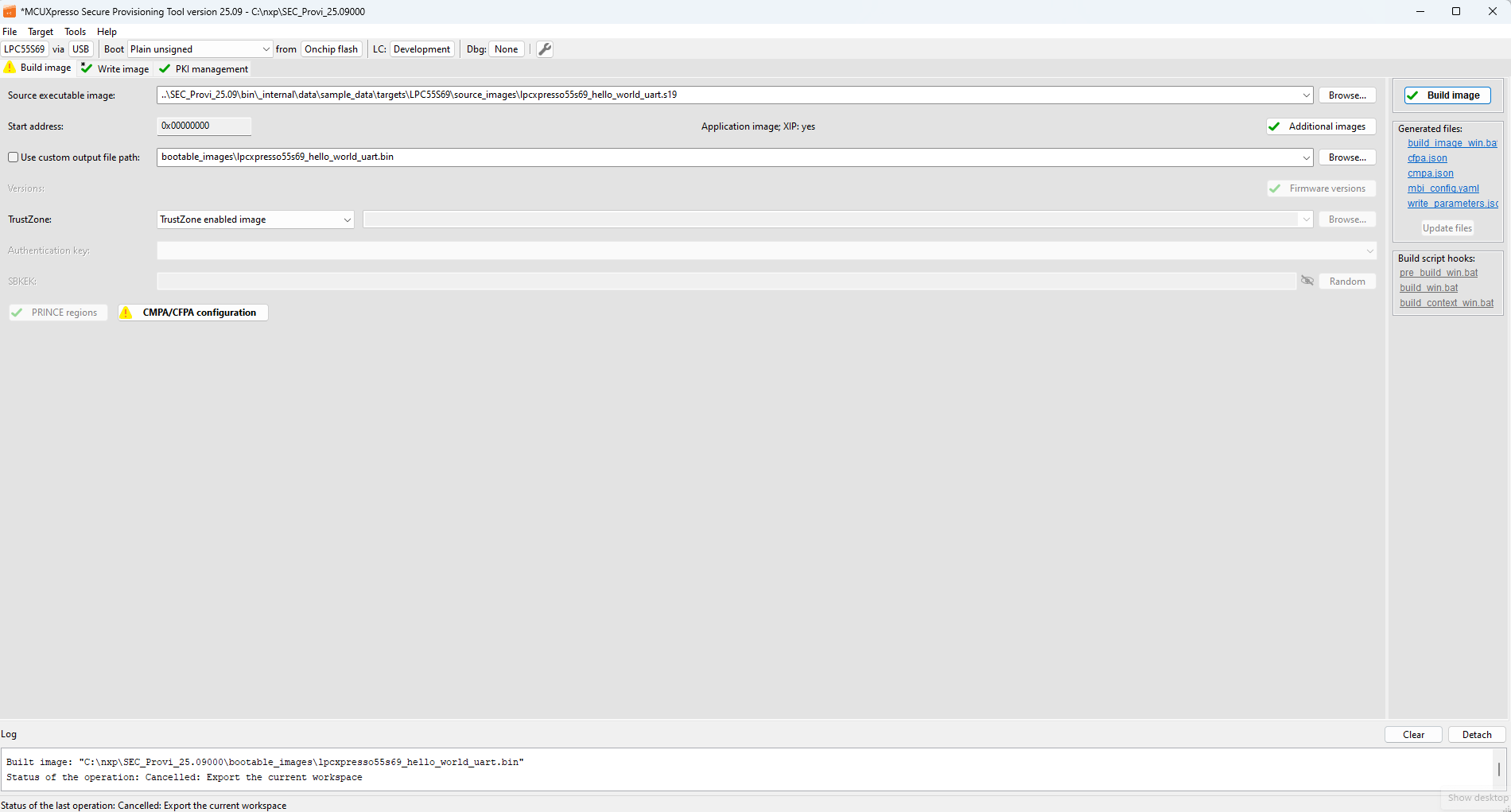

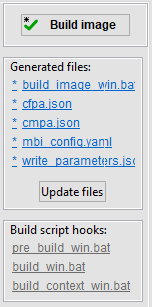

Build image panel

There is a build panel with the Build image button and a list of generated files on the right side of the build page. The Build image button updates all files and executes the build script. The icon on the button displays an asterisk (*) called “dirty flag” if the build script is not updated or is not successfully executed. The same indication is also displayed in the Build image tab.

The generated files below are displayed as clickable links, and the file content is displayed if you click them. The file name starts with an asterisk (*) if the file on the disk is not updated. It might be caused by changes in the configuration. Move the mouse cursor over the * to see the details about changes/differences.

Note: The differences are not supported for binary files or large changes.

This information is updated in the background with some delay, so it might take a couple of seconds before the real status is displayed. Until the information about the file is updated, the file icon is ? (question mark).

The Update files button allows updating all files without the execution of the script.

For the EdgeLock 2GO use case, there is an icon for each file that must be uploaded to the EdgeLock 2GO server.

Build script hooks

Build script hooks are displayed in the Build image panel below the generated files. Hook scripts are called before or during the build script execution. The gray label means that the file does not exist in the workspace yet. After clicking, a new file is created with the content from the example and opened for modification. If the file exists, the label is blue and after clicking the file is opened. For details, see Script hooks workflow.

Source image formats

SEC supports several formats for source image: ELF, HEX, BIN, or SREC/S19 (S-record). The image format is then unified into the format required by the build script, and this conversion is done inside SEC (the prior build script is called).

The SEC Tool partially parses the image to retrieve the entry point, to detect whether the image is XIP and validate the target address. In the S19 file format, the entry point can be listed explicitly, while for the other formats the entry point is retrieved from the interrupt vector table (so the interrupt vector table must be at the beginning of the application image).

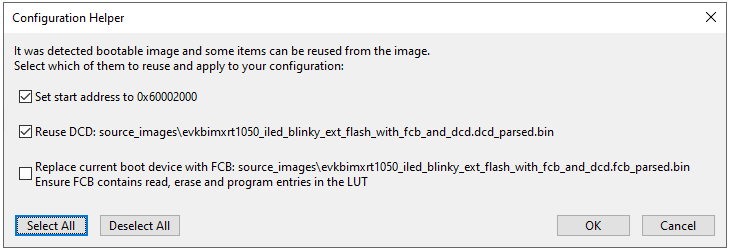

For some processors, MCUXpresso SDK examples contain a bootable image including FCB configuration. The SEC Tool supports splitting of the bootable images into pieces (FCB, DCD, XMCD sections), and reusing the parts to build a new bootable image. Once a bootable image is selected and the parser accepts the image, the tool offers to reuse specific parts and if confirmed, the configuration is updated.

Configuration Helper

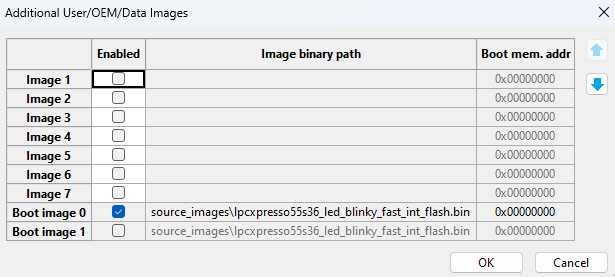

Additional images

This dialog allows the user to specify up to 8 user images that will be written into boot memory together with the application. For i.MX 9x processors, the dialog allows specification of up to 16 user images as the processors support primary and secondary container sets. The configurable options (columns) depend on the image format. They are different for AHAB images and the other processors.

The configuration is represented as a table, where each row represents one user image. Columns represent configurable features for each image. A description for each feature can be found in the tooltip. All processors except the i.MX 9x family have the last image reserved for the application executable image, which is automatically updated according to the build tab. The order of any image, except for the application executable image, can be changed by the up/down arrow in the right upper corner.

Additional User/OEM Images configuration

The examples of typical usage of the additional images:

add an image for the second core

add an application image for the secondary bootloader

add a binary data from an external file

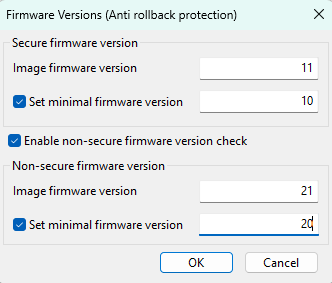

Firmware versions

The Firmware Versions dialog allows configuring anti-rollback protection. In the Firmware Versions dialog, specify Secure and Non-secure firmware versions for the image and optionally a value for CFPA or fuses that are used for anti-rollback protection as a minimal version.

Firmware versions dialog (LPC55S36)

Each panel (Secure firmware version and Non-secure firmware version) is used for a specific firmware version. These versions are checked during the SB file or AHAB image uploading against values in CFPA or against fuse values (the uploaded version must be equal to or greater than the appropriate value in the CFPA or fuses). The Secure firmware version specifies the secure image version checked during booting by the ROM.

Specifying values for the Non-secure firmware version is optional and can be enabled or disabled. The non-secure firmware version panel is visible only for processors that support the Non-secure firmware version.

Image firmware version. This version is included in the bootable image and/or it is checked in the SB file or AHAB image. The value must be greater or equal than the minimal firmware version.

Set minimal firmware version. Specify the minimal firmware version stored in CFPA or in fuses for enabling anti-rollback protection. The value must be equal to or smaller than the specific image firmware version. If the value is not specified, it can be specified in the OTP/PFR configuration dialog or the default value can be used.

XMCD configuration dialog

The configuration dialog allows customizing parameters for simplified XMCD. These parameters are specific for the selected XMCD memory interface, it can be either:

FlexSPI/XSPI interface for the HyperRAM/APMemory or

SEMC interface for SDRAM

The XMCD configuration dialog can be reached by the XMCD Edit button on the Build image view when FlexSPI/XSPI RAM or SEMC SDRAM is selected.

The Import button allows importing simplified configuration from a YAML or binary file. The Reset to defaults button allows returning to default settings.

TrustZone configuration file

TrustZone and related features of the ARM processors can be pre-configured by data from the application image header at boot time instead of setting the registers from the application code. TEE (Trusted Execution Environment) tool from MCUXpresso Config Tools allows you to export the TZ-M preset data for use in SEC Tool. Follow these steps to modify the existing example application, export the TZ-M file and add it into the application image.

To create, export, and import a TrustZone file, do the following:

Open an SDK example:

From MCUXpresso IDE:

In the Quickstart panel, select Import SDK example(s)….

Select the example to import.

In Project Explorer, open the context menu of the imported secure project.

From MCUXpresso Config Tools:

On start, select Create a new configuration and project based on an SDK example or hello world project.

Clone one of the TrustZone enabled (secure) projects.

Open the TEE Tool:

In MCUXpresso IDE:

In the menu bar, select MCUXpresso Config Tools > Open TEE.

In MCUXpresso Config Tools

Select the TEE tool from the Config Tools Overview.

In Security Access Configuration > Miscellaneous, use the Output type drop-down list to select ROM preset.

Configure security policies of memory regions as you see fit (for details, see User Guide for MCUXpresso Config Tools (Desktop) document GSMCUXCTUG

In the menu bar, select File > Export > TEE Tool > Export Source Files.

In the Export window, specify the JSON file download folder and select Finish.

Remove the BOARD_InitTrustZone() call from the SystemInitHook(void) function and tzm_config.h include located in the main application file (for example, hello_world_s.c)

Alternatively, basic TZ-M-preset JSON data included within the SEC layout can also be used as a starting point template for further modifications of TrustZone pre-configuration. Device-specific template files are provided in the sample_data\targets\<processor>\trust_zone_template.json

TrustZone templates provided in SEC Tool:

The TrustZone template format v1 contains all registers/options with default preset values. As SAU and AHB are disabled in the template, the template is expected to be customized before use.

The TrustZone template format v2 contains a list of commands for register initialization. The template provides a description of the YAML format and is expected to be modified before it is used.

After the JSON file has been downloaded, you can import it in SEC:

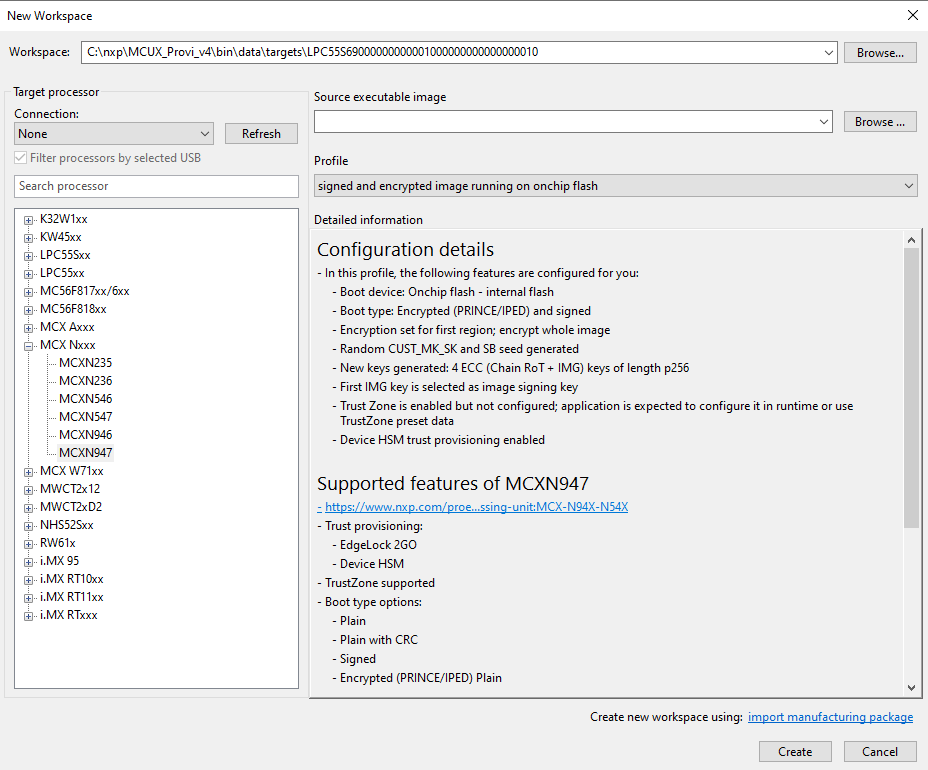

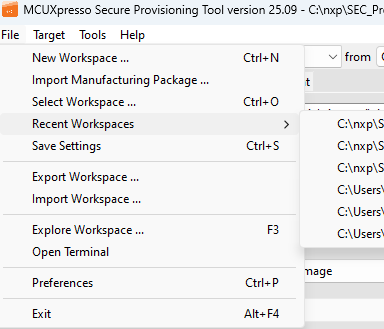

In the menu bar of SEC, select File > Select Workspace … and choose a workspace. Alternatively, create a one by selecting File > New Workspace ….

In the Build image view, switch the Boot type to Signed or Unsigned with CRC.

Use the TrustZone pre-configuration drop-down list to select TrustZone enabled image with preset data.

Click Browse to navigate to the location of the stored JSON file and select Open to import it.

It is possible to use YAML format instead of JSON to import TZ-M preset data into SEC.

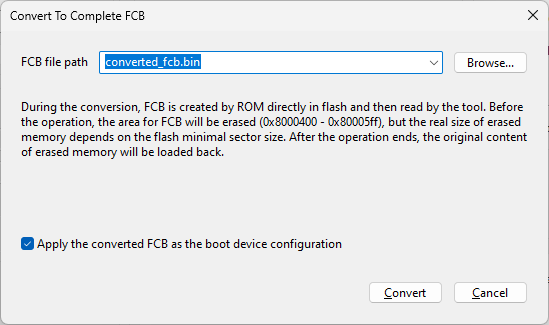

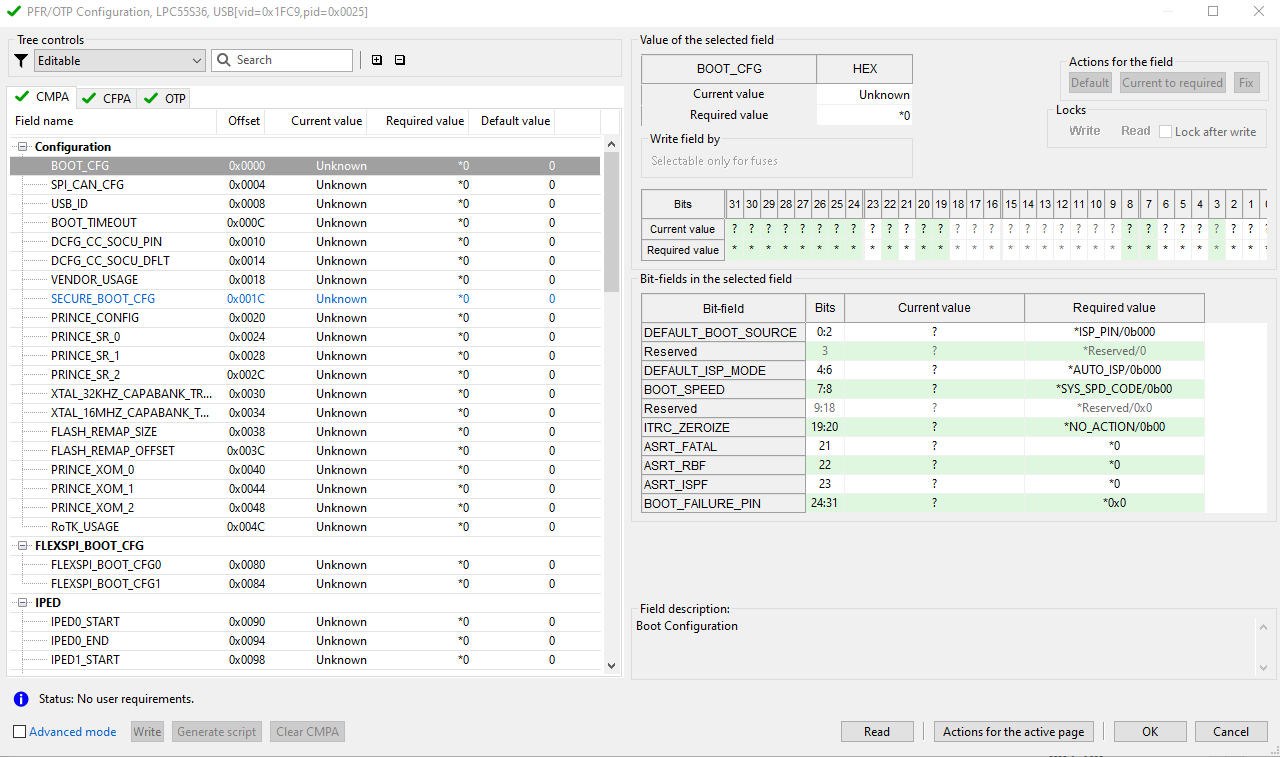

OTP/PFR/IFR/BCA/FCF configuration

The configuration dialog allows configuring:

One-time programmable fuses

CFPA and CMPA pages from Protected Flash Region (PFR)

ROMCFG/IFR page from Information Flash Region (IFR)

Bootloader Configuration Area (BCA)

Flash Configuration Field (FCF)

Use the configuration dialog to:

Review the configuration prepared by SEC

Read the current configuration from a connected processor

Customize the configuration

Lock the configuration (this feature is available for some fuses only)

In the OTP (One Time Programmable) Configuration, the configurable item is called a fuse. In the PFR (Protected Flash Region), BCA, FCF, and Information Flash Region (IFR) Configurations, the configurable item is called a field. The content of the dialog depends on the selected processor.

OTP Configuration

Primarily all changes in the configuration dialog will be applied as part of the write script - except for Advanced mode.

The configuration window contains three main areas:

Table of all fuses/fields (generally called items) on the left-hand side

Detailed information about the selected fuse/field on the right-hand side

Buttons bar in the bottom of the view

The width of the two main areas can be adjusted using the splitter.

Table of all items

PFR Configuration supports two pages: CFPA (Customer In-field Programmable Area) and CMPA (Customer Manufacturing/Factory Programmable Area). The IFR Configuration supports one-page called either ROMCFG (ROM Bootloader configurations) or IFR. Each page represents a separate list of fields organized in a tree. In OTP Configuration, all fuses are displayed in a single tree. The items in the tree are organized into logical groups. The tree of all items is displayed in form of a table, with the following columns (a column might not be displayed if the feature is not available for the processor):

Name : Human-readable name of the item. Some names may not be public and are available as a restricted data package. See the section about restricted data in Preferences.

Offset or shadow : Offset of the item address or offset of the shadow register address

# : Index of the item (parameter for blhost to access the fuse)

R/W/O : Status of read/write/operational locks retrieved from the processor. For more information, see Locks.

Current value : The current value of the item read from the processor (hexadecimal)

Required value : The hexadecimal value required by SEC or by the user. Values preset by SEC are highlighted in blue and can be modified only in Advanced mode.

Default value : The default value of the item (hexadecimal) - after reset value.

Note: On some devices (KW45xx and K32W1xx), there are fuses with width bigger than 32-bit, for example, 256-bit keys, and 512-bit version counters. These long fuses are displayed in several rows in the table and have a common # index (fuse index).

Tree-filtering toolbar

It is possible to filter items displayed in the tree. There are predefined filter types in the dropdown list with a description in the tooltip. It is also possible to search for an element by name using the text box.

The toolbar also contains two buttons allowing to expand or collapse all groups.

Item editor

In the right part of the dialog, the following details are displayed for the selected item:

Table with current and required item value as a hexadecimal number

Current state of the read and write lock

Selection, where the fuse will be written (see Burn fuse/write field).

Table with current and required item value as a binary number

Table with current and required item value as bit-fields value (only if the item is split to bit-fields)

Description of the selected object (group of items, fuse, field, bit-field)

Read from connected device

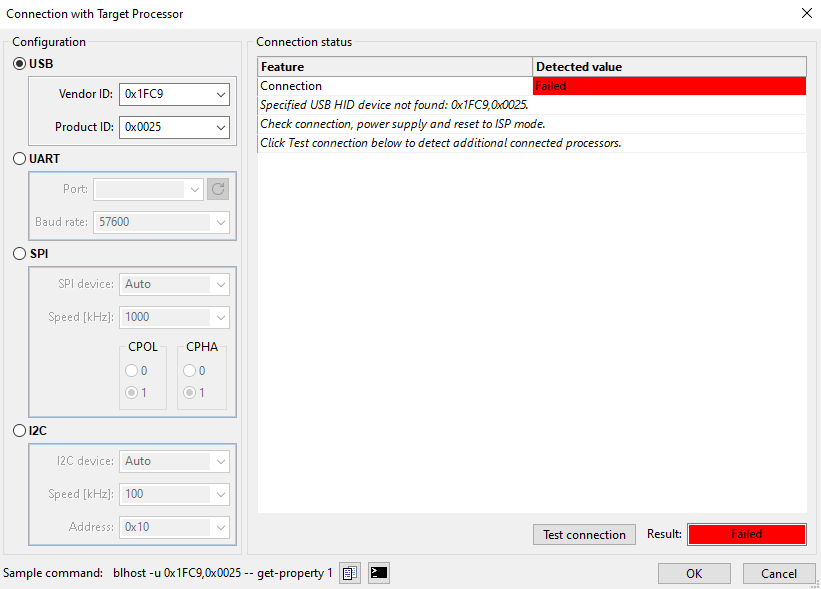

Before you start the OTP/PFR/IFR/BCA/FCF Configuration tool, it is recommended to check in the Connection dialog if the board is connected to the host. If the target device requires a flashloader (RT10xx, RT116x/7x, and RT118x), it is recommended to click Start flashloader in the Write image view to ensure that the communication with the device can be established.

After the Configuration tool is open, it will offer to load current fuse values from the processor. This feature is optional and can be done also anytime later using the Read button. The Preferences dialog contains an option to configure the initial read operation.

The read operation consists of the following steps:

Read locks to find which fuses are readable

Read current fuse values

Detect individual write locks (if applicable for the processor, see Locks for details)

Required value

Items that must be written based on a selected configuration (for example contains preset value), are highlighted in blue. The remaining items, by default, either do not have any required value - displayed as * (asterisk) OR if default value is applied, they are displayed as *<value> (for example *0). The required value for these items can be specified:

As a 32-bit hexadecimal number

By bits. Click the value in the second row of the Bits table to toggle the bit, double-click to remove the requirement from the bit.

Per bit-field (only if the register contains bit-fields)

For some bit-fields, the value is selectable from a drop-down list; otherwise, it is specified as a decimal or hexadecimal number (with 0x prefix).

For items wider than 32 bits the value can be specified only as a HEX string. HEX string represents a sequence of bytes in the order, as they will be stored in the memory.

Burn fuse/write field

In the OTP/IFR configuration, it is possible to select the source where the fuse is burnt or the field is written:

Write a script

SB file that writes the application image

Provisioning FW can be either the device HSM SB file or the SB/BIN file used during provisioning (it depends on the processor).

The available options depend on the configuration, so for example if shadow registers are used, no other option is enabled.

Locks

Locks are available in OTP Configuration to lock fuses. A lock block specifies an access restriction to the fuse - usually a read or write restriction. The locks must be programmed at the end of the development cycle when the rest of the configuration is already stable and tested and will not be changed. Locks are also used in IFR ROMCFG configuration. Here, the lock block specifies a write-access restriction to the ROMCFG block as each 16-byte block can be written only once. Similarly, the locks are also used in IFR configuration. Here, the lock specifies the write-access restriction to the IFR field as each 4-byte field can be written only once.

Two types of LOCKS are supported in SEC:

Global : Configured in a separate fuse usually called LOCK. The configuration is applied to several other fuses or shadow registers. READ, WRITE, or OPERATION locks exist, each type blocks the corresponding access to the fuse.

Individual write locks : For some processors, it is possible to apply a write-lock for a single fuse. Also, some fuses can be written only once and a write-lock must be applied. Both these features are presented as Lock after write checkbox, see description below. The Lock after write checkbox is also used to indicate a write restriction to the ROMCFG block or the IFR field.

The status of all locks is updated during the Read operation. The status is displayed in the fuses table, specifically, in these columns:

R : Display status of read lock for the fuse

W : Display status of write lock for the fuse (combined status of global and individual write lock)

O : Display status of operation lock for the fuse

The following icons are to represent the lock status:

Table 2. Lock icons

Icon |

Description |

|---|---|

No icon |

The fuse does not support a corresponding lock. |

|

Lock status unknown |

|

Fuse access unlocked |

|

Fuse access is locked |

Lock after write checkbox is dynamically enabled or disabled based on the selected fuse.

Individual write-lock is not supported for selected fuse - checkbox is disabled and unselected

The fuse must be locked after the first write - checkbox is disabled and selected

Individual write-lock is optional - checkbox is enabled

For fuses configured to turn on individual write-lock, the following icon is displayed in the Required value column in the fuses table:

Table 3. Individual write-lock

Icon |

Description |

|---|---|

|

Fuses configured to turn on individual write-lock |

On RT116x, RT117x, and RT118x devices, the lock after write status cannot be detected, so the fuse might be displayed as unlocked even if it was already locked.

Lock validation

OTP Configuration reports a warning in the case the write-lock for the fuse is on and the fuse value is not fully specified.

Calculated fields

Some registers or bit-fields contain a value that is calculated using the value of another bit field. For example:

One item may contain the inverse value of another item

One bit field contains the CRC of other bit-fields of the item

This feature is supported in Configuration as validation, the error is displayed in the case the calculated value does not match or the source value for the calculated item is not specified. See the following chapter for details about validations and problem resolutions.

Validation and problem resolution

The configuration provides validation of the required values and the problems are indicated by the icon in the window title, in the tree, and, if the item is selected, in the details section, in all editors.

In the BITS editor, the problem is displayed only for bits affected by the problem. It allows fixing the problem easily by clicking the affecting bit value (for example, inverting the required value of the bit).

For all errors, you can use the Quick Fix button. This button fixes all errors within the selected item. Make sure to review the changes made by the quick fix to ensure that the newly applied value matches your expectations.

Warnings may also be displayed for the current value read from the processor to inform the user when the value is invalid

Note: Specific OTP/PFR fields are used for the transition of the device through its life cycle, granting conditional or locking down access to various debug resources in the device once programmed. As the best practice, it is recommended to program these registers once the secure boot has been verified as functional. Incorrect values in these fields may render the platform nonfunctional or no longer accessible for recovery. On some platforms, these registers include special “valid” semantics - for example, on the LPC55Sxx processors, the DCFG_CC_SOCU_PIN and DCFG_CC_SOCU_NS configuration fields include bits that must be programmed as the inverse of all the other fields in the register for the configuration to be valid. The Fix Problems facility enforces this constraint only if the register contains a non-zero value - that is, an explicit user configuration of the register has been detected.

Advanced mode

By default, it is recommended to apply the modified configuration into a workspace settings file and the Write script, so it is applied together with the bootable image. However, sometimes it might be necessary to burn a single fuse value, in which case you can use the Advanced mode. The Advanced mode is designed for standalone usage of the Configuration tool and allows you to:

Write a required value directly to the connected processor (see Write/Burn)

Generate the script to write the required values

Modify all required values, even the ones preset by SEC-PFR Configuration

Clear CMPA page; apply default values to the whole CMPA page

Additionally, the reserved items values are read from the connected processor in this mode (most likely useful to NXP engineers only).

The Advanced configuration is not expected to be applied to the write script, so the OK button is disabled. The Export button can be used to store the created configuration into an external file.

Note: Advanced mode is not needed for normal workflow supported by the SEC Tool, it must be used only for the use cases not supported by the tool.

Write/Burn

The Write/Burn operation burns all required values into the connected device including all locks. The burn operation consists of the following steps:

Read current values from the processor

Update validation problems

Generate write/burn script

Execute the write/burn script

Bear in mind that the burn operation is irreversible. It is recommended to:

Double-check all values being burned

Double-check all items being locked

Double-check all problems reported by the configuration

Generate write/burn script and review the content

There is a difference between Burn and Generate Script:

The Burn operation is optimized for the selected processor. The fuse will not be burned if the value matches or the fuse is locked. For CFPA and CMPA the whole page is always written.

Warning: The ROMCFG block can be written only once.

Generate Script is expected to be used on an empty processor. It contains the configuration of all fuses and it might fail if any fuse is already burnt.

PFR/IFR/BCA/FCF and OTP differences

Items in OTP Configuration are called “fuses” while items in other configurations are called “fields”.

Fuses in OTP Configuration are burned item by item, so you can specify a single requirement only. The fields in IFR ROMCFG Configuration are written by 16-byte blocks, so completed 16-byte requirements must be specified. PFR always updates the whole page, so if no requirement is specified, the default value is used.

Selection `burn fuse by` is supported only for fuses.

Locks selections are supported for fuses, IFR fields, and the IFR ROMCFG blocks.

CFPA, CMPA, BCA, and FCF pages can be written multiple times whereas the ROMCFG block or IFR field can be written only once.

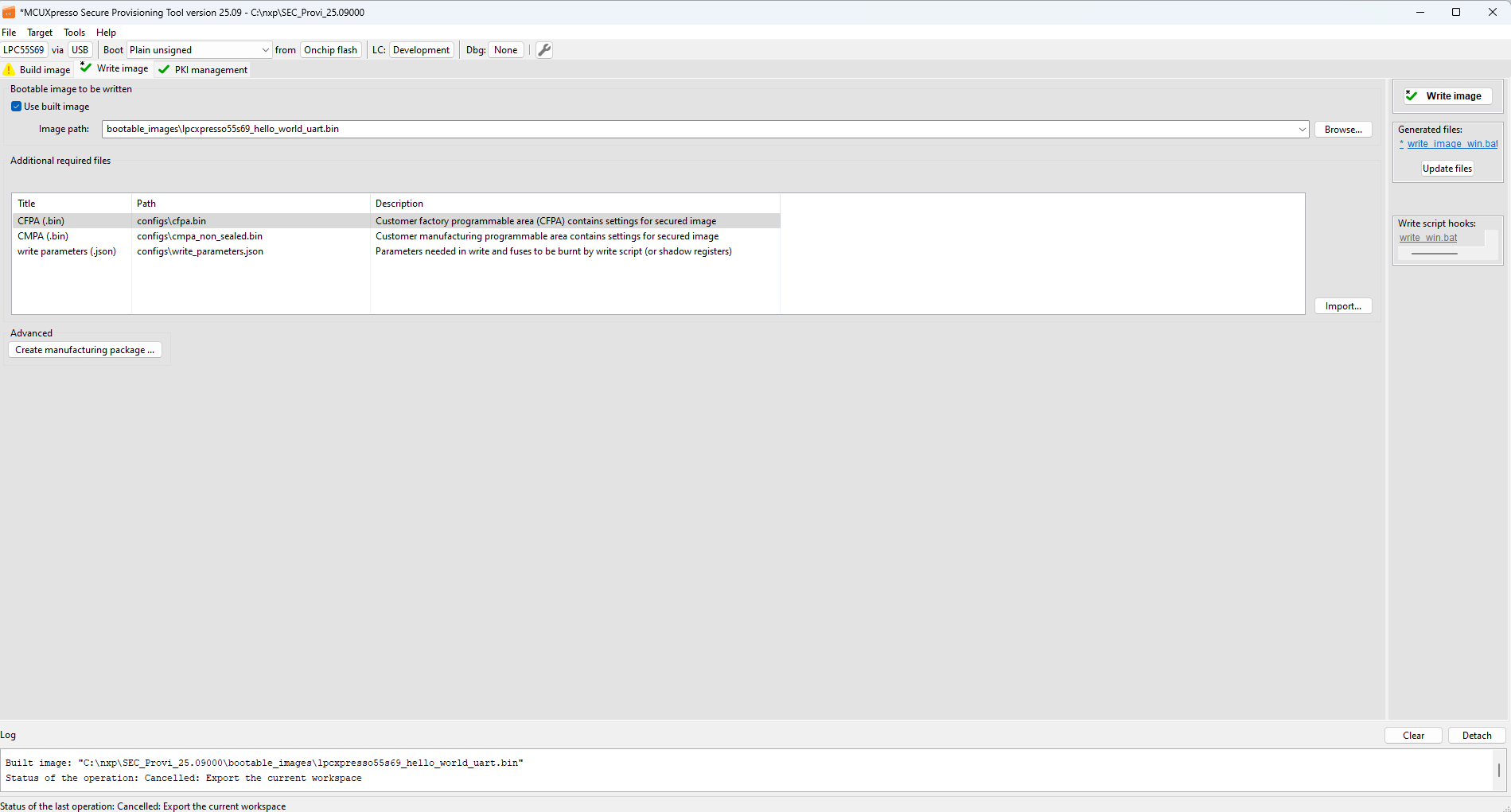

Write image

Use the Write image view to write an image into the boot memory, burn platform fuses and configure the selected life cycle to achieve a secure boot. The write image tab may have a dirty flag on the icon, which means there are changes that were not included in the last build operation.

Write image (LPC55Sxx)

Controls on the write image view

Use built image : If checked, the output of the Build image operation will be used for the write.

Bootable image : Path to the image that will be written into the target device. The file extension is specific for processor and boot type, it is either BIN for bootable images or SB for secure-binary capsules. The binary image must be in “nopadding” form without the FCB block, as the FCB block is written in a separate step.

Additional input files : Display required input files for the Write image operation. The contents depends on the processor, boot type, and other build options. By default, the contents are output files of the Build image operation. You can manually replace each file with a custom file using the Import button.

Start flashloader : Allows you to initialize and start the flashloader on the connected processor. If security is enabled in the chip, the signed flashloader is created automatically. Useful if you want to use blhost from the command line.

Test life cycle : Opens dialog that can set a temporally advanced life-cycle state. This allows it to test processor behavior in a selected life-cycle state without burning the fuses. The board must be connected by a debugger probe.

Disable flash security : Opens a dialog where the user can specify a backdoor key to disable flash security. The backdoor key can be obtained from the FCF configuration, a bootable image, or entered manually. As a final step in the flash disabling process, it is possible to execute a mass erase to clear the entire flash memory.

Write image panel : There is the Write image panel with the Write image button and the file name of the write script, on the right side of the window.

Generated files : The Generated files panel has the same functionality as Generated files.

Write script hooks : The panel with the hook script that is called during the write script execution. The gray label means that the file does not exist in the workspace yet. After clicking, a new file is created with the contents from the example and opened for modification. If the file exists, the label is blue and after clicking the file is opened. For details, see Script hooks workflow.

Before clicking the Write image button, ensure that the board is connected and configured to the ISP mode. If any irreversible operation is done by the write script, a confirmation dialog with details appears.

Manufacturing package

The manufacturing package is a ZIP file that contains the write script and all other files needed for the write operation and it is designed to send the files into the factory for production. The manufacturing package can be created using the button Create manufacturing package … on the Write image page. The dialog is described in Manufacturing workflow.

In the factory, the manufacturing package can be imported using main menu > File > Import Manufacturing Package…. For more information, see Manufacturing operations.

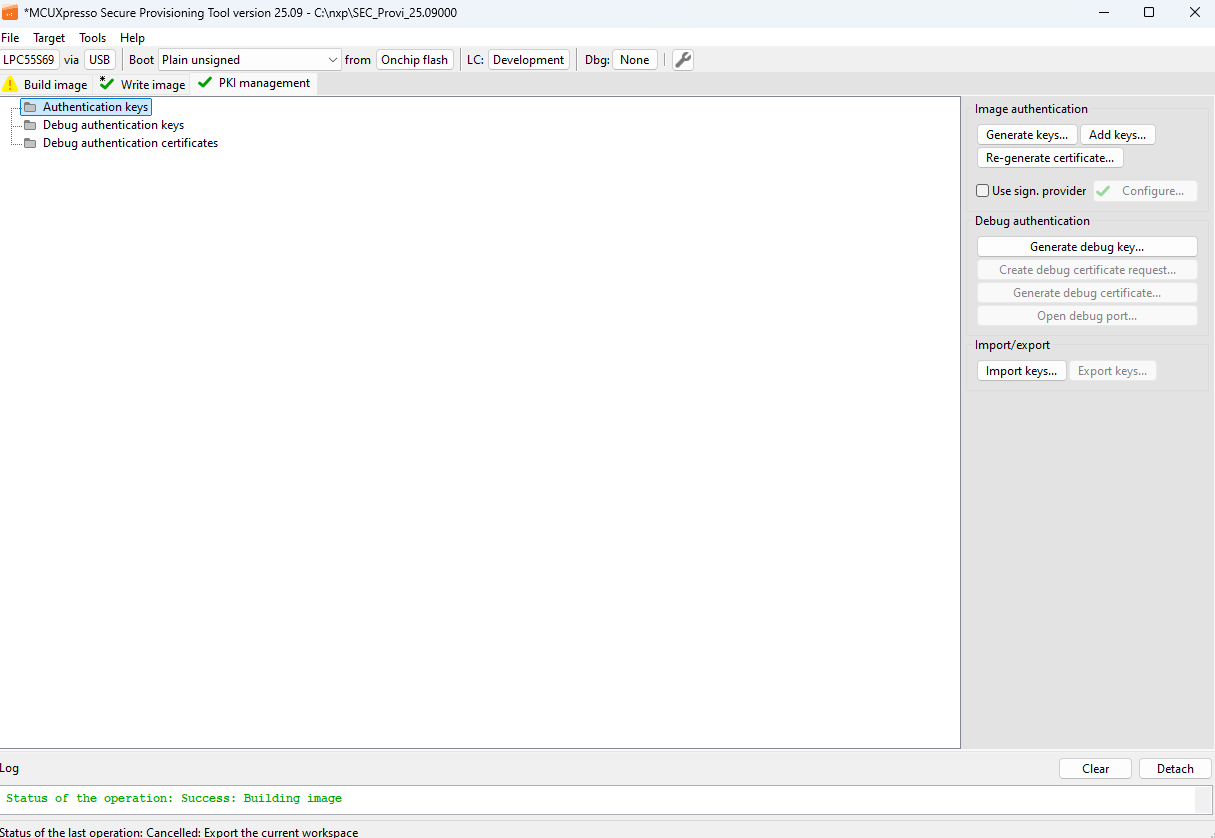

PKI management

The PKI management view displays the list of asymmetric keys and certificates used to validate the authenticity of the image. Generated keys can be exported for later use. PKI management allows generating the following:

keys for image authentication

key pair for debug authentication

PKI management (LPC55Sxx)

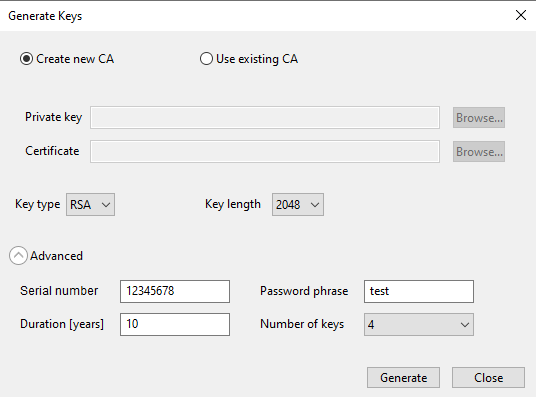

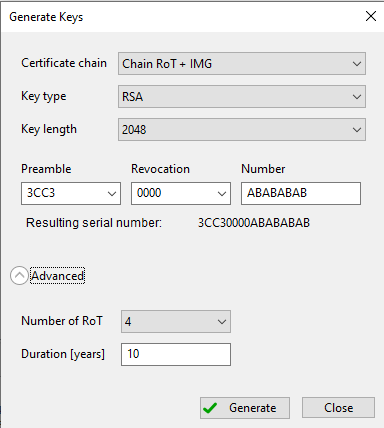

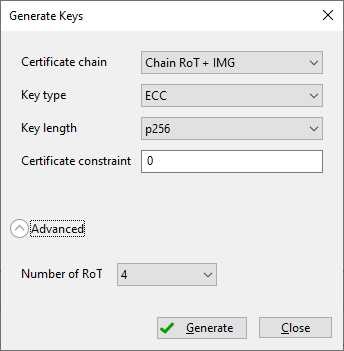

Generate keys

Authenticated images rely on a Public Key Infrastructure (PKI) set of certificates. SEC includes a graphical interface that simplifies the generation of a PKI-compatible with selected processor.

Generate keys (RT1xxx)

Generate RSA keys

Generate ECC keys

Description of the controls in the generation dialog:

Create new CA : This option allows generating keys including a certificate

Use existing CA : Enable the use of user-specified CAs. Certificate and Private Key must be in PEM format.

Private Key : Path to the private key file

Certificate : Path to the certificate file

Key type : Generated key type. The following types are supported:

RSA: asymmetric keys using RSA cryptography

ECC: asymmetric keys using ECC cryptography

ECC+PQC: dual asymmetric keys for dual signing scheme, ECC is used as a primary signature and PQC as a secondary one.

Key length : Generated key length in bits. For the dual keys scheme, the drop-down contains all available combinations supported for the processor.

Serial number : The value is used for key revocation. The serial number for RSA keys on LPC55Sxx and RT5xx/6xx consists of three parts: preamble, revocation, and number. The revocation part is validated against the revocation field in OTP/CFPA.

Password phrase : Secure generated CA with the specified parameter. This feature is supported only for RT10xx processors.

Duration [years] : Set certificate validity to the specified duration in years. For supported devices, it is necessary for signing purposes only, as the duration is not directly verified in hardware.

Number of keys : Set to the number of keys to be generated. Most processors support up to 4 keys, with a recommended default of 4.

Certificate chain : The depth of the keychain.

Preamble : Prefix of the serial number, mandatory fixed value

Revocation : Middle part of the serial number, 16-bit revocation ID - this value should match the IMG_REVOKE field in OTP/PFR (CFPA) on the device.

Number : Suffix of the serial number bytes used to uniquely identify the certificate/key.

Certificate constraint : Used for revocation of the image signing key, validated against the revocation field in OTP/PFR. The detailed (processor-specific) information is displayed in the tooltip.

Refer to the OpenSSL documentation for additional details about the Password, Serial, and Duration options.

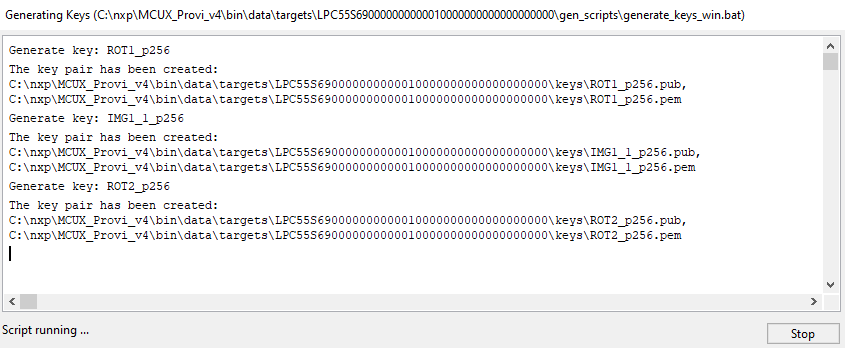

Once all parameters have been specified, click the Generate button. The key generation script output is displayed in the progress window.

Generate Keys - Progress

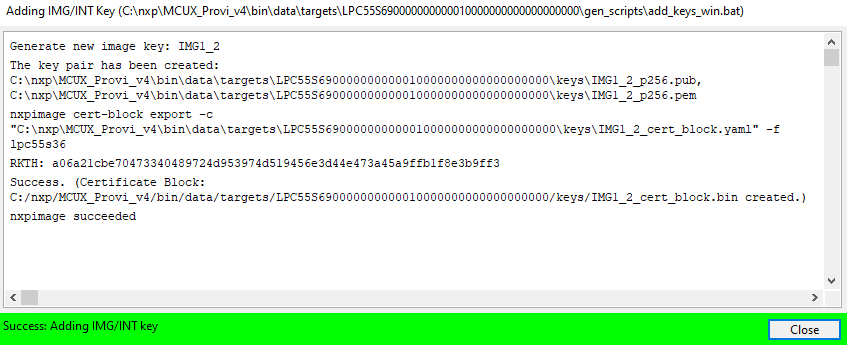

Add keys

Once keys have been generated in the Generate keys dialog, you can add additional image keys using the Add keys dialog.

IMG key path : Path of the image (ISK) key to be generated and added.

CSF key path : Path of the CSF key to be generated and added.

Key : Key type to be generated, either Image for image signing or Intermediate for creating a chain of keys

The other items are described in Generate keys.

Once you have specified your preferences, click Ok to add the keys. The output will be displayed in the progress window.

Add Keys progress

Re-generate certificate

The SEC Tool allows re-generating a ROT or image key certificate, in case the certificate is missing or it is needed to specify different parameters (for example for certificate revocation). Select the key with the certificate and click the Re-generate certificate… button. In the dialog, review the parameters, update the serial number and confirm re-generation. The current certificate will be backed up into the backup folder and then rewritten.

The parameters for re-generation are the same as the parameters for generation; the description can be found in the previous chapters.

Import/Export keys

You can export generated keys for later use with the help of the Export function. To export keys:

Select Export keys in the PKI management view.

In the dialog, navigate to the location you want to export the keys to, and select Select folder.

Note: Export keys also export workspace configuration, including symmetric keys, for example, SBKEK for LPC or BEE user keys for RT10xx devices.

You can later import the keys into a new workspace using the Import function. The operation makes a backup of current keys and settings inside the current workspace. The symmetric keys, for example, SBKEK for LPC55Sxx/RT5xx/RT6xx, BEE user keys for RT10xx, OTFAD keys data for RT116x/RT117x/RT118x/RT5xx/RT6xx devices, and IEE keys data for RT116x/RT117x/RT118x are restored from the imported folder.

To import keys:

Select Import keys in the PKI management view.

In the dialog, navigate to the folder containing the

keysandcrtssubdirectories with the keys info you want to import and select Select folder.

To import external keys that were not exported from the SEC Tool:

Generate new dummy keys and export them into a new folder; ensure that the number of keys matches the keys being imported.

Overwrite the keys in the exported folder with the files being imported (rename keys being imported so they match the naming convention used in the SEC Tool).

Import the keys back from the folder.

Debug authentication

The Debug Authentication (DA) buttons are displayed in PKI management only for processors that support DA. The Generate debug key button is always enabled, Create debug certificate request and Open debug port are enabled only if the DA key exists. Generate debug certificate is enabled in a workspace with authentication keys. The Generate debug key button opens a dialog box for creating a debug authentication key pair. Generate debug certificate request allows to create a request that will be sent to the OEM, from which a debug certificate can be generated. The Generate debug certificate buttons display a certificate where the OEM selects the keys and sets the rights that will be granted to the certificate holder. The Open Debug Port dialog prepares the connected device for debugging by using the DAC.

Note: For more information, see Debug authentication workflow.

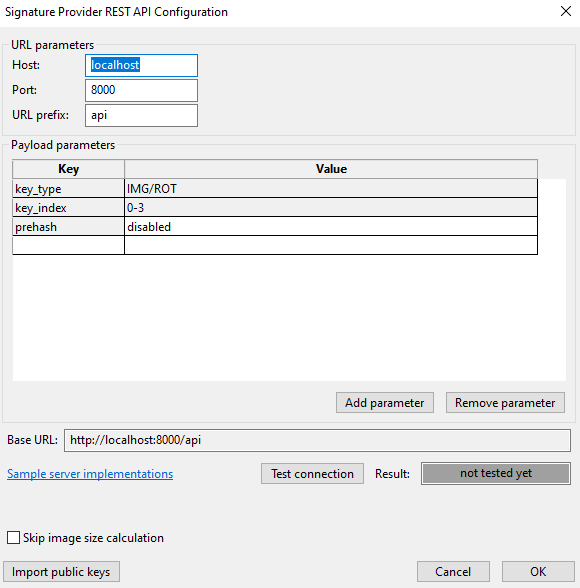

Signature provider

Signature provider allows using a custom provider for the authentication instead of keys stored on a local machine. Signature provider requires a custom implementation of an HTTP server with a simple API providing the authentication.

Once the Use sign. provider checkbox is selected, it is possible to open the configuration dialog. When enabled, the present keys from the workspace are moved to the back-up folder. The signature provider server is used as the source of public keys and provides signing. Configuration set in Signature Provider Configuration dialog is used in configuration files for build, key certificate regeneration, and DAC generation(cert_block, mbi_config, sb_config, debug_credentials_config).

Signature provider configuration

URL parameters

Required parameters from URL of the server:

Host host name or IP address of the server, accepted symbols as specified in RFC 3986. It is recommended to use localhost, as the HTTP communication is not secure. For communication to another computer, it is recommended to implement a proxy server forwarding the communication via a secure channel (HTTPS).

Port port number of the service, integer number.

URL prefix REST API prefix, use an empty string if there is not any.

Payload parameters

Payload parameters are passed as a JSON payload with each request sent to the server. Each parameter is identified by a unique key and contains a text value. The following keys are reserved for the tool:

type - used by SPSDK to identify signature provider type.

host, port, url_prefix - used to specify server connection.

data - used as key for data payload of request.

key_type - used by SEC Tool to specify whether image or root key should be used; supported values are IMG or ROT.

key_index - used by the SEC Tool to identify which private key should be used. The value is a decimal number in the range 0-3 set by selecting a key from build tab ROT1 -> 0, ROT2 -> 1, IMG1_1 -> 0, IMG2_1 -> 1 and so on.

prehash - allows selecting whether to send complete data for signing or hash only. The hash algorithm can be selected from the drop-down menu; however, it is recommended to use `default`.

Signature provider server API

Signature provider API must implement the following three endpoints, and optionally one additional endpoint:

sign

sign handles signing of the given data block; the request sends the data to be signed with a private key specified by optional parameters. Example of the signature request for MCX947 with ROT1 or ROT1-IMG1_1 selected as signing key: ‘http://localhost:8000/server/sign’ json payload:

Certificate signing with ROT1 key:

{

″data″: ″hex string of certificate block to be signed″,

″key_type″: ″ROT″

″key_index″: 0

″prehashed″: ″none if not prehashed, hash algorithm name if data is prehashed″

}

Image signing with IMG1_1 key:

{

″data″: ″ hex string of image block to be signed″,

″key_type″: ″IMG″

″key_index″: 0

″prehashed″: ″none if not prehashed, hash algorithm name if data is prehashed″

}

signature_length

signature_length returns the signature length in bytes.

verify_public_key

verify_public_key verifies that the used public key forms a valid key pair with the private key that is on the server. The public key is sent as a data payload, the RSA key is sent in NXP proprietary format and the ECC key is sent in DER format. To identify the private key that should be matched with this key, use optional parameters. In the case of matching keys, return “true”.

This API is designed to detect a problem if the server is using a key different from the client one. For environments where such validation is not needed, the implementation can return simply “true”.

public_keys_certs

public_keys_certs is an optional endpoint. If implemented, it allows importing public keys from the Signature provider dialog into the SEC Tool. The SEC Tool expects the response from this endpoint to be a tree of Authentication keys, ROT keys at the top level, and IMG keys as the leaves. The structure of the response is described in <install_folder>/bin/_internal/schema/signature_provider_key_tree_schema_##_##.json. In general, any tree that can be generated from the Generate keys dialog can be imported, with the limitation of one child key for the root key. RSA trees do not need to have the same key length for each subkey.

Server examples

Server examples are part of the SEC Tool distribution. There are Python script examples with the server implementation. These examples are described in Signature provider workflow.

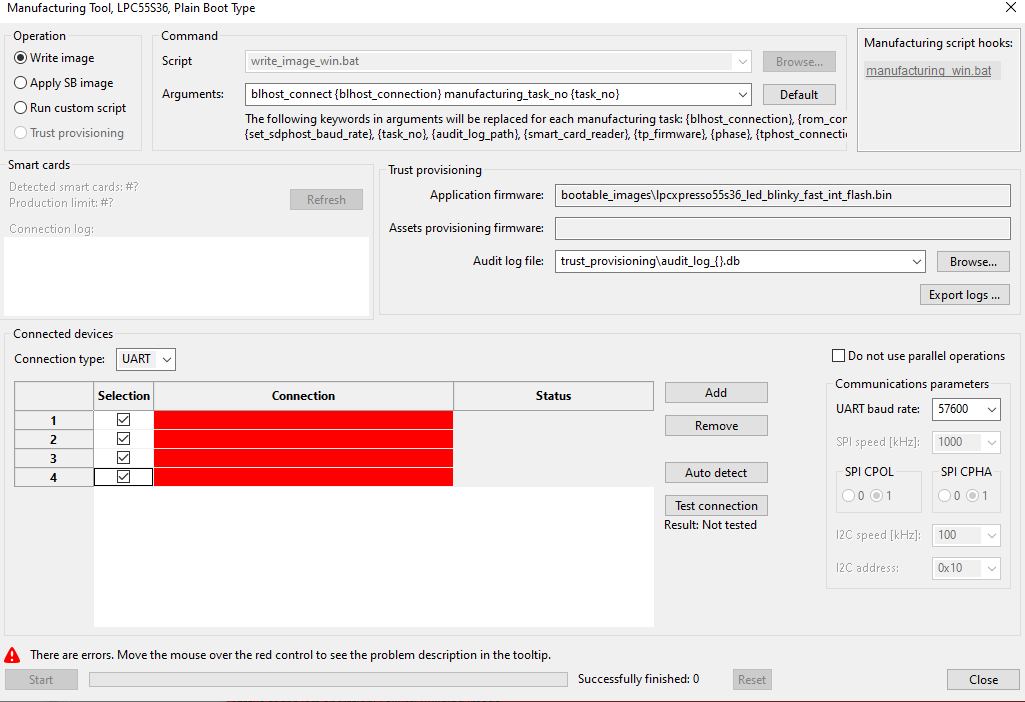

Manufacturing Tool

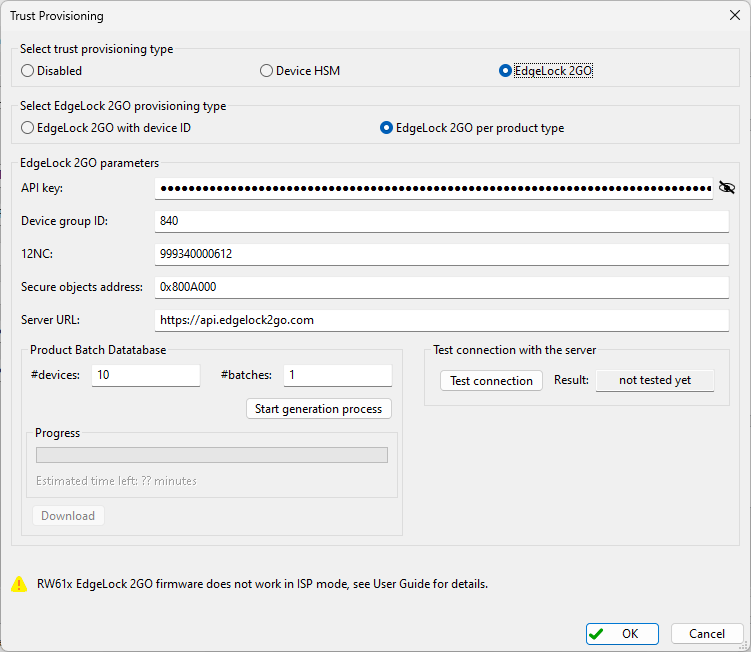

Use Manufacturing Tool to provision several devices connected to the host at the same time. Manufacturing Tool can be accessed from Tools in the menu bar. The devices can be connected to the host using USB or UART or SPI or I2C. The user interface is made of these areas: Operation, Command, Connected devices, Communication parameters, and the button bar. If trust provisioning is supported for the processor, there is also a Trust provisioning area.

Manufacturing Tool

Operation : The Operation area contains radio buttons representing different operations to choose from.

Write image : Performs the same operation as Write image. Before use, the image must be built in the Build image view, and the Write image view must not show any errors.

Apply SB image : Uses an SB (Secure Binary) capsule to update the existing image of the processor. For most of the processors, the SB file is created during the build secure image operation and is located in the bootable_images subfolder of the workspace by default. For RT10xx/RT116x/RT117x/RT118x processors, the SB file must be created manually, as it is currently not supported by SEC.

Run custom script : Uses a custom script to configure provisioning. It is assumed that the script is a modified SEC write script accepting SEC parameters (especially connection parameters). Exit status 0 is considered a success.

Command : The Command area contains parameters needed for the operation selected in the Operation area. The parameters vary based on the selected operation.

Script (Write image, Run custom script, Trust provisioning) : Path to the write or custom script. To locate the custom script, use the Browse button.

SB file (Apply SB image) : Path to the SB capsule. To locate the file, use the Browse button.

Arguments : List of arguments used during the operation. Use the Default button to revert any changes. The keywords enclosed in curly braces in arguments will be replaced for each manufacturing task. You can find the complete list of keywords with descriptions in the tooltip.

Manufacturing script hooks : The panel with the hook script that is called at the start and end of the manufacturing script execution. The gray label means that the file does not exist in the workspace yet. After clicking, a new file is created with the contents from the example and opened for modification. If the file exists, the label is blue and after clicking the file is opened. For details, see Script hooks workflow.

Trust provisioning : Configuration of the trust provisioning operation.

Application/Assets provisioning firmwares : These file paths are listed for information only.

EdgeLock 2GO API key : Access key for EdgeLock 2GO server. It can be specified here or in environment variable

SEC_EL2GO_API_KEY.EdgeLock 2GO server: Test connection : Allows testing the connection with the EdgeLock 2GO server.

EdgeLock 2GO product batch DB : Path to EdgeLock 2GO secure objects database used for the per product (offline) flow

Connection type : Allows selecting a communication interface with the processors.

#phases

: A number of phases being executed for one device. The USB device identification passed to write the script might change after reset (see USB path). If the write image script supports the USB connection, the script is executed in phases, which basically means the script is invoked several times with different manufacturing_phase argument. Each phase is finished by reset and the USB identification is updated before executing the next phase. This parameter allows overriding the number of phases being executed and a forced custom number. Value disabled means that the phases are not used. It is recommended to use the default value. If the default value is selected, the current number of phases is displayed in the tooltip. The custom value shall be used only if the write script was modified manually.

Do not use parallel operations : the check box allows disabling parallel operations in the manufacturing. This can be used if any problem with parallel operation is detected.

Connected devices : The connected devices area contains an interactive table displaying all connected devices. The tool can detect and program devices connected using USB only if they are in ISP mode.

Columns:

Selection : allows users to enable/device; each device is configured in the table. If the device is de-selected, the next autodetection keeps the device de-selected.

Connection : allows users to enter manually the device name or path.

Status : Displays the status of the connected device. After the operation was executed, the log file can be opened by clicking the entry in the Status column

Buttons to modify Connected devices:

Select all : A button to select all devices in the table below.

Deselect all : A button to deselect all devices in the table below.

Autodetect : A button to detect automatically all devices connected to the host for a selected connection type. It is the recommended usage. For more information about the USB path, see USB path.

Add : A button to manually add a device (add an empty row to the table).

Remove : A button to remove the selected device from the table (remove the selected row).

Test connection : A button to test (ping) the selected devices. This feature might be useful for UART, SPI, and I2C devices where the detection of the communication device (COM port or USB path) does not imply that the connection with the processor is established. Therefore, a test connection is recommended before starting the manufacturing operation.

Export logs : Allows exporting manufacturing logs as a ZIP file. Besides exporting all logs, it is possible to export logs for a specific day only.

Load KeyStore (Apply SB image for RT5xx/6xx) : Load KeyStore from external flash before uploading the SB file.

Communication parameters : Configuration of the connection with the device. The Baud rate option allows selecting a value from the drop-down list or specifying it manually. The detailed description of the parameters can be found in the Connection chapter.

Crystal freq. [kHz]

: Frequency of the external crystal used as a clock source for the processor. This is used only for lpcprog tool.

Button bar : The Button bar contains action buttons and displays any warnings and alerts.

Start : Starts the selected and configured operation. You can observe the progress of the operation in the adjacent progress bar.

Successfully finished : Label with the number of successfully finished operations. This number is incremented automatically and stored in the settings file in the workspace.

Reset : The button allows resetting the “Successfully finished” counter.

Close : Closes the Manufacturing Tool without running the operation.

USB path

The Manufacturing Tool supports the use of Serial, USB, SPI, or I2C connection. In most cases, the Auto-detect function will be sufficient for detecting the connected devices. The USB path is used to identify the USB device for USB, SPI, or I2C communication, so the devices with the same USB VID and PID can be identified uniquely. It differs depending on the operating system. The description of the USB path format can be found in the SPSDK documentation.

The Manufacturing Tool supports automatic USB path update that may happen during the manufacturing operation because of the following reasons:

On some operating systems, the USB path changes after each device reset.

RT1xxx processors in ISP mode have different VID and PID compared to the VID and PID of the flashloader application (which cannot be booted at the start of the manufacturing phase).

After the update, the Manufacturing Tool automatically executes the second part of the script that finishes the required operation.

Note: RT10xx devices in ISP mode have different VID and PID compared to the VID and PID of the flashloader application, which is uploaded to the target to program the flash. Auto-detect searches for devices with PID and VID when the target is reset in the ISP mode. If the flashloader is active on the device, reset it into ROM bootloader mode. The manufacturing process is slightly different: as a first step, the flashloader is uploaded to all boards and its USB path is retrieved. After this step, the rest of the process is executed in parallel.

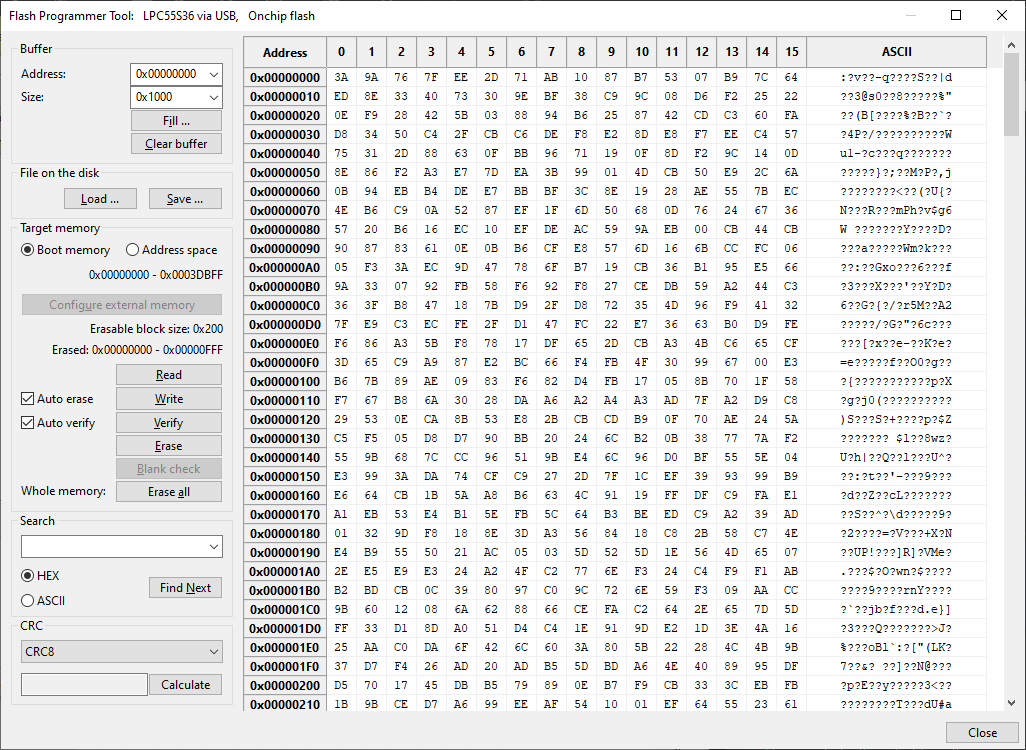

Flash Programmer

Flash Programmer is designed to read/write from the currently selected flash memory and supports all flash types including internal flash, external NOR and NAND flash, SD card, and eMMC. Flash Programmer can be accessed from Tools in the menu bar. The processor can be connected to the host using USB, UART, SPI, or I2C and must be in ISP mode (as the tool internally uses the blhost or lpcprog protocol). Flash Programmer can be used to prepare data for writing, or just to display or modify saved memory blocks even if no device is connected. The left side contains the action toolbar and the right side contains a buffer of the memory content in hexadecimal and ASCII formats. The tool has additional functionalities: “Auto erase” and “Auto verify”. To display memory value from some address, fill in the start address into the Address combo and required size (in Bytes) into the Size combo. Click Read and the value read from memory will be displayed. The result of the operation is displayed in the bottom-left corner. If the operation ends with failure, more detailed info about the encountered error is displayed in the tooltip. The settings of the flash programmer window are not saved into the workspace. They are discarded if the tool is closed.

Flash Programmer Tool

Buffer : The buffer represents a part (copy) of the flash memory that will be written or read from the processor. The buffer is defined by the address, size, and content.

Address : Specifies the start address of the buffered space. The address cannot go lower or above the start or end address of the target memory.

Size : The size of the buffer specifies how many bytes should be read or written or erased. The size is limited to 16 MB.

Fill … : Opens a dialog that can fill the buffer with value (byte, word, double word, or random). Word and double word can be applied as big or little endian.

Clear buffer : Clears displayed values and set the size to 0.

File on the disk : Load/save operations with a file on the disk.

Load … : Loads the file into the buffer;

.srecand .hexfiles are loaded with formatting (start address), other file types are processed as binary files without start address information. The address is the start address in the buffer where the value should be loaded, size tells what portion of data from the start should be loaded. The loaded data are merged with the existing buffer context (for example, the buffer can be extended) and the overlapping areas are overwritten. Load is also supported via drag-and-drop functionality, allowing files to be added directly to the gridSave … : Saves buffer or portion of buffer into a file. The supported file formats are

.srec, .hex, and.bin.

Target memory : This block provides basic operations on target memory. The hex range on the top is the working memory range of the selected memory.

Selection of the memory type : Select which memory should be targeted:

Boot memoryrefers to the same memory as selected in the tool panel.Address spacerefers to the entire address space of the processor. TheBoot memorycan be re-configured directly from the tool using button below, while for theAddress spacethe tool expects the memory is already available.Configure : Tries to configure the connected memory. It executes the same memory configuration as in the Boot memory configuration. If it is memory with FCB, then the last step of configuration tries to read the size of the minimal erasable block. The command is supported for external flash only, it is disabled for internal flash.

Erasable block size : Defines the minimal erasable block size. This value is read from FCB if available or from the boot memory configuration for memories that do not use FCB. If no erasable block size is found, it is not possible to compute the erased size.

Erased : The address range, which will be erased by the erase operation. The address range is determined by the buffer address and size, and it is aligned to an erasable block boundary. If the buffer is not aligned with the erasable block size, a warning is displayed.

Read : Reads memory of a given range to fill the buffer. For memory types with ECC, reading is not possible if the memory is erased.

Write : Writes values in the buffer to the memory, see also the options “Auto erase” and “Auto verify”

Verify : Checks whether the values in the buffer match values in memory, values that do not match are highlighted with red color and the tooltip displays the value that is in the memory

Erase : Erases the memory, always erases the closest upper multiplication of minimal erasable block size.

Blank check : Checks if the memory is blank or not supported for internal flash.

Erase all : Erases entire memory.

Auto erase : On the write operation, the memory is erased before writing.

Auto verify : After the write operation, verifies that that buffer was written properly.

Search : Search for a value in the buffer; the value can be provided as HEX numbers grouped as bytes (“FF AA”, “12 A3 00”) or ASCII (“abc”, “hello world”). The found value is highlighted in blue and the start address is displayed in the left corner. CRC : Compute CRC of the selected type for the buffered data.

SB editor

The SB Editor Tool is designed to create custom secure binary files for updates of the SW, data, and/or processor configuration. The SB editor supports SB formats: SB2.x, SB3.x, and SBx and also supports both regular SB file and device HSM SB file. The SB editor can be started using the command main menu > Tools > SB Editor. When the SB editor is opened for the first time, and the workspace already contains a YAML file with the SB configuration (which is recommended), the SB Editor Tool offers to import the file.

SB files are generated using the nxpimage or nxpdevhsm command-line utilities, so the SB editor produces a configuration YAML file that is used as input for those tools. The SB editor is a smart GUI editor for the YAML configuration file. In the GUI, there are also supported “$” extensions (see high-level commands and $ variables), that are translated into the corresponding values in YAML.

SB editor contains the following main UI parts:

Top buttons bar : The bar that allows selecting the SB file type, import, export, or clear the current configuration.

Properties : The view that allows specifying properties for SB file generation.

Commands : The view that allows specifying the sequence of commands that shall be executed in the SB file.

Output : The panel, where the output files (the configuration YAML file and the resulting SB file) can be specified. The button View allows updating YAML configuration file and open in external editor. The button Generate allows to (re-)generate the resulting SB file.

Status and bottom buttons : The buttons that allow creating manufacturing package and starting manufacturing tool. The OK/Cancel buttons allow closing the SB editor with or without saving the configuration into the workspace.

File type

The SB editor supports the creation of:

Secure Binary - a regular SB file that is secured by OEM keys specified on the Build view;

Device HSM SB file used for device HSM secured by device-specific keys. Creation of this SB file requires the processor to be connected to the computer. For details, see Connection.

The properties and commands for each file type might be different, so switch the file type may affect the current configuration.

It is recommended to avoid modification of the device HSM SB file because modifying default sequence of commands may cause a risk of exposing OEM assets during factory provisioning. The SB file is sent to the processor in blocks, and command atomicity across blocks is not guaranteed - external link manipulation may interrupt execution. Command order matters - an incorrect sequence could leak sensitive assets if the device falls back to ISP mode. Proceed only if you fully understand the security implications.

Properties view

The properties view allows editing general properties and property lists. In case the processor contains any list-type property, it is selectable on the left side and the right side displays a property editor table. If no list-property is supported for the processor, the GUI displays just a property editor table.

The property editor table contains the following columns:

Group : The properties are logically grouped (for information only).

Property : Name of the property (for information only)

Value : The value of the property. If the value is not specified, there is an empty string. The value can be of the following type: integer number; string; predefined options (drop-down list), which include logical type (#true/#false); file path

Resolved value : In case the value is specified in the form of ${variable}, this column contains the value of the variable; otherwise, it is the same as the value.

The property description is displayed in a tooltip.

Commands view

The view allows specifying the sequence of the commands that will be stored in the SB file and will be executed in the target processor. There are two types of commands: high-level and low-level. High-level command sequences are sequences of low-level commands that are typically used in SB files and are designed as SEC-tool specific extension of the low-level commands. These commands simplify creation/modifications of the SB file and will be replaced by low-level commands during the generation of the configuration YAML file. The names of all high-level commands start with “$”. High-level commands do not have any arguments, and the parameters of the commands inside cannot be modified. However, it is always possible to replace a high-level command by a set of the corresponding low-level commands and then customize the low-level commands. High-level commands may contain an optional low-level command that is stored into YAML only if all variables for the low-level command are defined. This is used if a high-level command might be extended in some configurations. Use a high-level command instead of a low-level command, as high-level commands are updated with the SEC Tool configuration.

The commands page contains the following panels:

The command sequence : The list of commands to be generated into the SB file. It is possible to select whether there will be displayed $ variables or real values.

Buttons bar : The bar is used to control the command sequence with the following buttons:

Table 4. Buttons bar

Button |

Description |

|---|---|

|

Add - to add the selected command into the current sequence |

|

Delete - to remove the selected command from the current sequence |

|

Move - to move the selected command up or down in the current sequence |

|

Expand - to expand a high-level command sequence into the list of low-level commands |

All available commands : The tree with all available commands is divided into “High-level command sequences” and “Low-level commands”.

Variables : Table of $ variables applicable as command arguments. It is possible to select whether the table should contain all variables or command-specific variables (the property-specific variables will be not be displayed).

Selected command : This panel shows the parameters of the selected command in a table.

Command parameters

: The parameters for the selected command can be specified in the table at the bottom of the commands page. The first column represents the command itself and the other columns represent the command parameters. If the parameter is required, not specifying it results in an error. The description of the parameter is displayed as a tooltip. Use ${variable} for parameter values, because these variables are updated within the SEC Tool configuration.

For a high-level command, an informative description is displayed instead of a parameter.

$ Variables

To allow reuse of a SEC Tool configuration for the SB file generation, $ variables are provided. Names of these variables consist of the $ character and the name is enclosed in curly braces (for example, ${family}). The variables are used for properties and command parameters. For properties, the $ variable name matches the name of the property. The list of all variables can be found on the Commands page at the right. It is possible to filter the variables to hide variables for “properties” or display all variables. The variables are not editable; however, it is possible to copy the name or value into the clipboard.

Validation

All the input values are validated and any problems are displayed in the window. Before generating the SB file, the YAML file is validated using the JSON schema. If any validation fails, the SB file cannot be generated.

It is recommended to create a SEC Tool workspace with the SB file, import the working configuration into the SB editor and start updating the working configuration.

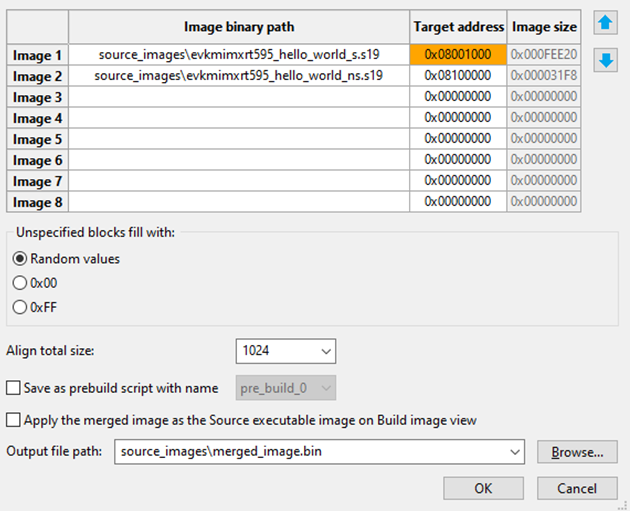

Merge Tool

The Merge Tool allows users to merge up to 8 images, given by the user, into one single binary image.

Merge images tool

The configuration allows users to specify:

Images : Table to specify the path and target address for each image that used to be merged

Fill pattern : Pattern used to fill empty gaps between images, such as random value, 0x00, or 0xFF

Align total size : Align the size of the entire merged image

Pre-build script option : Merge script is executed when the OK button is pressed, but it can be stored as given pre-build script to be executed before build script.

Apply the merged image as the source executable image : Allows applying the merged image as a source executable image on the Build image view when the merge script is done

Output file path : Path where the merged binary image will be stored on a disk